Top 25 FAQs About Feed Pellet Machines

When choosing a feed pellet machine, many users have similar questions. To help you better understand the product and make informed decisions, we have compiled the following common questions and answers.

1. How do I choose the right model of feed pellet machine?

When selecting a model, consider factors such as the size of your farm, the type of raw materials, target output, available power supply, and overall budget.

If you are unsure which model is suitable, please contact us. We will recommend the right option based on your specific needs.

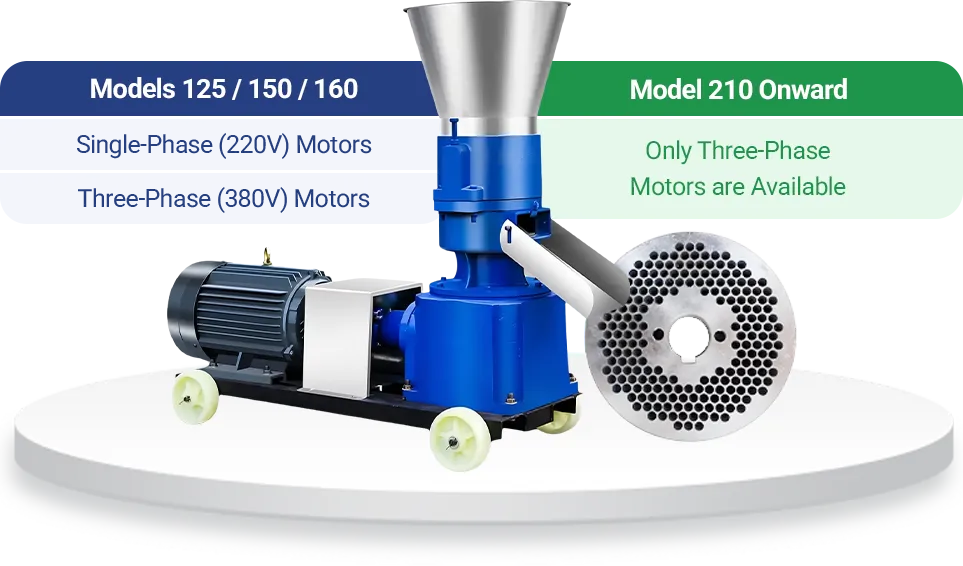

2. Do your feed pellet machines run on single-phase or three-phase electricity?

Models 125, 150, and 160 can be equipped with either single-phase (220V) or three-phase (380V) motors. From model 210 onward, only three-phase motors are available.

All motors can be customized to match the voltage standards in your country or region.

3. Electricity is not available in my area. Do you offer non-electric pellet machines?

Yes. We offer feed pellet machines powered by diesel engines or PTO systems driven by tractors. These options work well in areas with limited or unstable electricity.

4. Can I use the machine right after purchase? Do I need to do anything before starting?

We recommend running a polishing mix before first use. This helps remove tiny burrs inside the die holes and improves pellet shaping.

Even if the die appears smooth out of the box, polishing helps the machine run more smoothly and extends the die's lifespan.

To make the mix, combine about 20% fine sand, 65% biomass powder or flour, and 15% vegetable oil. Feed it into the pellet machine and run it continuously for 40–60 minutes.

If needed, we can pre-polish the machine for you, so it's ready to use upon arrival.

5. Is the machine easy to operate?

Yes. The machine is simple to use and easy to set up. Just follow the manual to get started. We also offer video tutorials to guide you through each step.

6. What kinds of animal feed can it make?

By switching the die size, you can make feed for chickens, ducks, geese, pigs, cattle, sheep, rabbits, fish, pigeons, dogs, birds, and more. It meets the feeding needs of animals at different growth stages.

7. I'm not sure what die size to use. How should I choose?

Choose the die size based on the type and age of the animals you're feeding:

2.5 mm: For young rabbits, chicks, ducklings, goslings, baby pigeons, and small fish

3–4 mm: For rabbits, chickens, ducks, geese, pigeons, birds, and most fish

5–6 mm: For pigs, cattle, sheep, dogs, and horses

7–10 mm: For large animals like mature cattle, sheep, horses, and camels

If you're not sure which size works best, just tell us what animals you raise, and we'll help you choose the right one.

8. What if the die gets clogged and no feed comes out?

If the die is slightly clogged, try installing it in reverse and run some polishing mix with coarse materials like corn or old pellets. The friction can help push out the blockage.

For more serious clogs, remove the die, soak it in hot water, and then try the same method.

9. What materials can the feed pellet mill process?

It can handle corn, wheat, rice, bran, soybean meal, grass powder, rice husk, distillers' grains, oil residue, peanut shells, sunflower husks, vegetable leaves, fish meal, bone meal, and more.

As long as the materials are the right size, well-mixed, and properly moistened, they're suitable for pelletizing.

10. Do I need to grind the raw materials before pelletizing?

Yes, it's important. Grinding helps make the pellets more balanced in nutrition and easier for animals to eat. In most cases, the material should be under 2 cm long. For larger machines, up to 4 cm is fine.

Smaller pieces go through the machine more smoothly, improve output, and reduce wear.

11. Does moisture content matter?

Yes, it does. Aim for 10% to 15% moisture. You can start with dry materials and add a bit of water if needed.

Too much moisture can make the pellets rough, hard to shape, and difficult to release. They also don't store well. When the moisture is just right, the pellets come out smoother, dry faster, and are easier to keep fresh.

12. How can I tell if the moisture level is right during daily use?

The most accurate way is to use a moisture meter.

If you don't have one, there's a simple trick: Grab a handful of material and squeeze it. If it clumps slightly but doesn't drip, and breaks apart easily when dropped, the moisture is probably just right for pelletizing.

13. My formula includes a lot of grass. Can your pellet machine handle it?

Yes, it can. If your mix has a lot of grass or straw, we recommend using a roller-driven pellet machine. This type is better suited for high-fiber materials and gives smoother output with less risk of clogging.

14. Do the pellets come out well-formed? Will there be a lot of powder?

If the moisture is right, the forming rate can be over 90%. Too much powder usually means the material is too dry or the roller gap isn't set properly. If the machine clogs or the pellets come out lumpy, the moisture might be too high.

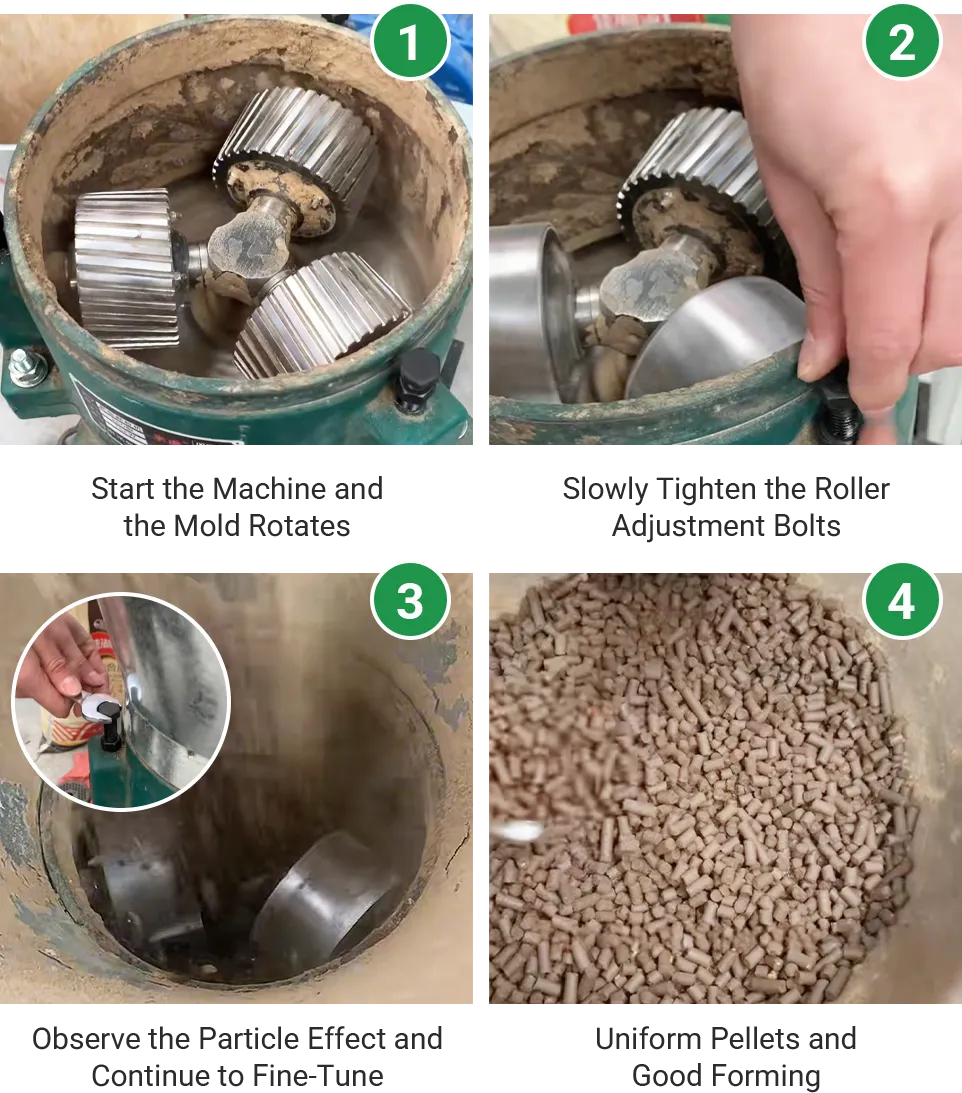

15. How do I adjust the roller gap?

Here is a simple step-by-step guide:

Start the machine: Turn on the machine and allow the die to begin rotating.

Add a small amount of feed: Feed in a little material to create light pressure between the die and rollers. Avoid running the machine empty.

Begin adjusting: Slowly tighten the roller adjustment bolts. When the rollers begin to turn together with the die, you have reached the initial contact point.

Fine-tune the gap: Observe the pellet quality. If the pellets appear loose or poorly formed, tighten the bolts slightly. If the machine sounds strained or feels overloaded, loosen them a little.

Final check: The rollers should turn smoothly with the die-not jammed, but not spinning freely. You should feel moderate resistance when turning them by hand.

The machine runs steadily, makes no unusual noise, and produces uniform pellets.

16. Can I adjust the pellet length?

Yes. You can control the pellet length by adjusting the distance between the cutter and the die surface.

The closer the cutter is, the shorter the pellets. The farther it is, the longer the pellets.

In most cases, the length can be adjusted between 1 and 3 centimeters.

17. Do I need to clean or maintain the pellet machine after daily use?

Yes. After each use, we recommend running some of your feed mix with about 20 percent cooking oil. This coats the die, reduces buildup, and helps the machine start smoothly next time.

In addition, grease the roller bearings about once a month. The gear oil in the gearbox should be replaced once a year to keep the machine running properly.

18. Can I use my own motor with your pellet machine?

It depends on the motor's speed and power.

Our machines are designed for 4-pole motors with a speed of 1,400 to 1,500 RPM. To ensure proper performance, your motor must match both the speed and the power requirements of the machine.

We recommend using a motor with the same power rating specified for each model.

19. Can this pellet machine make floating fish feed?

No. Standard feed pellet mills only produce sinking feed.

To make floating or semi-floating fish feed, you will need a specialized fish feed extruder.

20. Can I use this pellet machine for other materials, like cat litter, sawdust, or distillers' grains?

Yes. As long as the material is fine enough, the moisture is right, and the roller gap is set properly, the machine can form pellets.

That said, different materials require different compression ratios. It's best to check with us first to make sure it fits your needs.

21. Can I adjust the running speed?

No. The machine doesn't come with speed control.

The output rate mainly depends on the motor speed and how your raw materials behave.

22. How can I tell if a feed pellet mill is good quality?

Look at the die material, motor power, machine weight, and overall build.

High-quality dies are usually darker and may feel slightly oily. A strong motor helps the machine run smoothly. Heavier machines often mean sturdier parts.

Good welding, clean paint, and well-made gears also reflect solid craftsmanship. Don't judge by price alone-always compare the specs.

23. Does the feed pellet machine come with a warranty and after-sales service?

Yes. The machine has a 1-year warranty (excluding wear parts like the die and rollers).

If any non-human damage occurs, we'll provide free repair or replacement parts.

24. How long do the die and rollers last?

They're made from 20CrMnTi alloy steel, with high hardness and wear resistance.

Under normal use, they can run for 500 to 800 hours or more.

25. Is there anything I should pay attention to when using the machine?

Yes. Make sure there are no stones, metal, or other debris in the raw materials.

Don't push or force-feed by hand.

If the machine stops discharging or makes unusual noise, stop immediately and check the roller gap, material moisture, or die condition.

After each use, loosen the roller gap to avoid jamming and ensure smooth starting next time.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.