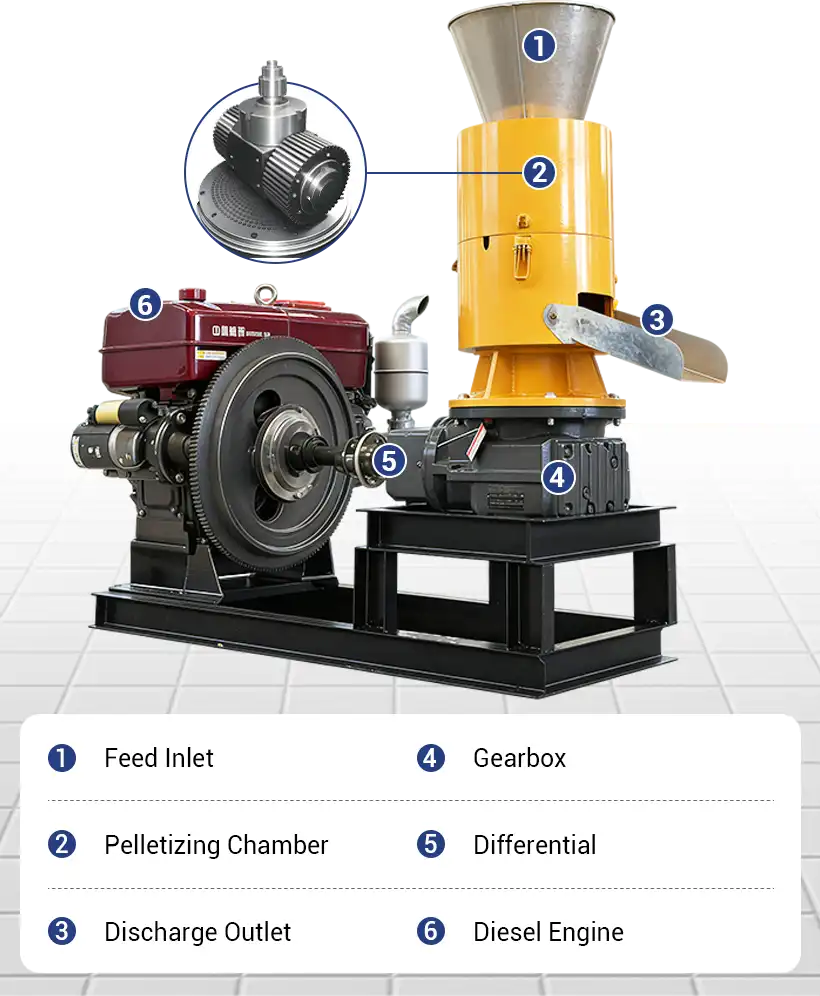

Diesel Biomass Pellet Machine

This diesel biomass pellet machine turns sawdust, straw, rice husk, and similar biomass materials into fuel pellets or bedding pellets, making it suitable for farms, forestry sites, and off grid production.

The diesel biomass pellet machine compresses sawdust, straw, rice husk, and similar materials into dense fuel pellets for heating, boilers, waste recycling, and animal bedding.

Because electric models need three phase power, this diesel unit runs independently in locations without stable electricity. It enables on site pellet production at farms and waste collection points, improving material use and lowering transport costs.

The machine consists of a diesel engine, gearbox, feed hopper, pelletizing unit with die and rollers, a cutting outlet, and lubrication points. The engine drives the main shaft through a belt or coupling. Material enters the chamber, is pressed through the die holes by the rollers, cut to size, and discharged. Wear resistant parts support stable pressure and long service life.

Raw material should be ground to a suitable size and kept at 12 to 18 percent moisture for proper forming. Changing the die size allows different pellet diameters, typically 6- 10 mm for heating use.

The design focuses on a compact layout, simple operation, and strong adaptability, enabling stable performance in outdoor or decentralized processing sites.

Video

Product Parameters

| Model | Power (HP) | Capacity (KG/H) |

| KB-200 | 18 | 150-200 |

| KB-250 | 25 | 200-300 |

| KB-300 | 35 | 250-350 |

FAQ?

What are the advantages of a diesel pellet machine?

A diesel engine provides strong low speed torque and keeps stable pressure under heavy loads. It works without relying on electricity, making it suitable for farms or sites without three phase power.

What materials can it process?

It handles pre ground biomass such as sawdust, shavings, straw, rice husk, bamboo powder, peanut shells, and bark. Material size should be about 3 to 5 mm, and moisture is best kept at 12 to 18 percent.

Do different materials need different die compression ratios?

Yes. Wood based materials usually work with a 1:5 to 1:6 ratio. High fiber materials like straw, peanut shells, or bark often need 1:6 to 1:8 to ensure proper density.

How long do the wear parts last?

Die and roller life varies with material. Wood based materials can reach 500 to 800 hours, while high fiber materials usually last 300 to 600 hours. Keeping spare dies is recommended for quick replacement or for switching compression ratios.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.