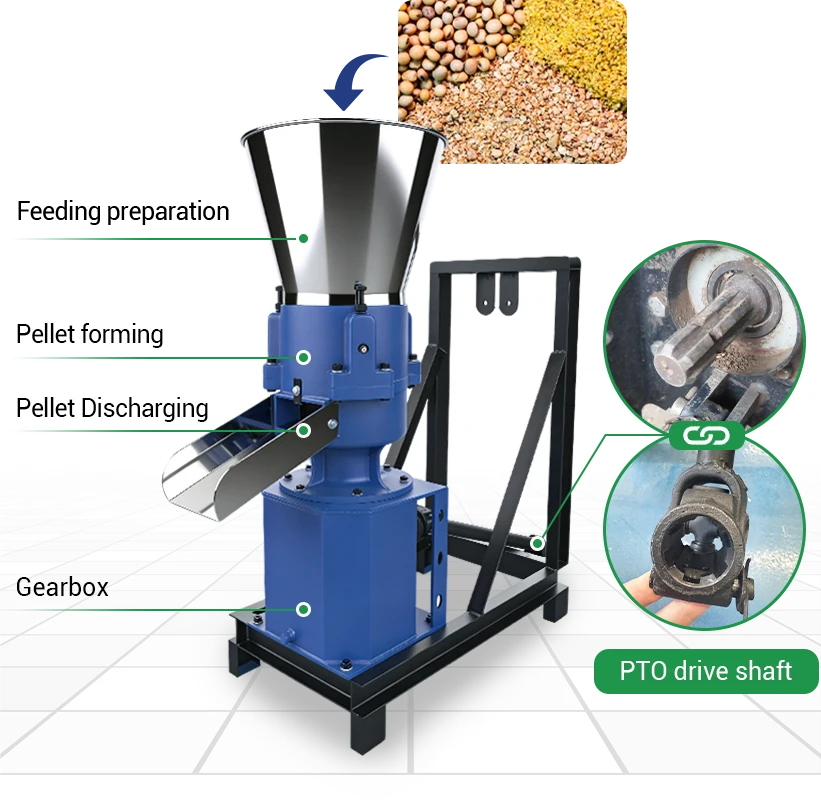

PTO Feed Pellet Machine

The PTO feed pellet machine runs on tractor power and works reliably in areas without electricity or with unstable supply. It can process common feed ingredients such as corn flour, wheat bran, soybean meal, grass powder, and crushed straw, making it suitable for farms, ranches, and mobile feed production.

The machine uses a flat die system and includes a PTO shaft compatible with multiple tractor interfaces, a torque increasing gearbox, rollers, die plate, feed hopper, and reinforced frame. Tractor power drives the gearbox and rotates the die, while the rollers press the mixed feed through the die holes. Heat and pressure help form dense, uniform pellets that discharge from the outlet.

The design focuses on power efficiency, stable pressing, and outdoor durability, allowing users to produce feed directly in the field or livestock areas. Pellet size can be adjusted by changing the die, with options from 2.5 to 8 mm to meet different feeding needs.

Video

Product Parameters

| Model | Tractor horsepower (HP) | Capacity (KG/H) | Roller |

| KD-125 | ≥6 | 60-10 | 2 |

| KD-150 | ≥6 | 80-150 | 2 |

| KD-160 | ≥8 | 130-200 | 3 |

| KD-180 | ≥8 | 150-220 | 4 |

| KD-210 2R | ≥12 | 200-250 | 2 |

| KD-210 3R | ≥12 | 200-300 | 3 |

| KD-230 | ≥15 | 250-400 | 3 |

| KD-260 3R | ≥22 | 300-450 | 3 |

| KD-260 4R | ≥28 | 300-500 | 4 |

| KD-300 | ≥35 | 500-700 | 4 |

| KD-400 | ≥85 | 900-1200 | 4 |

FAQ?

What advantages does a PTO feed pellet machine offer?

It runs on tractor power, needs no electricity or extra diesel engine, and is easy to move. This makes it suitable for field work and remote farms, with better value compared with similar powered machines.

What materials can it process?

It processes common feed ingredients such as corn flour, crushed corn, wheat bran, soybean meal, rice bran, grass powder, alfalfa, and straw powder. Moisture should stay between 12 and 18 percent for stable pellets.

Can it press biomass materials?

Not advised. Its pressure and die design fit feed materials. Biomass like sawdust and rice husks need higher compression and may cause poor forming or faster wear.

What should I pay attention to during use?

Ensure the tractor's PTO output matches the machine. Avoid working in heavy rain, provide basic water protection, and clean and lubricate the die and rollers after each use to reduce wear.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.