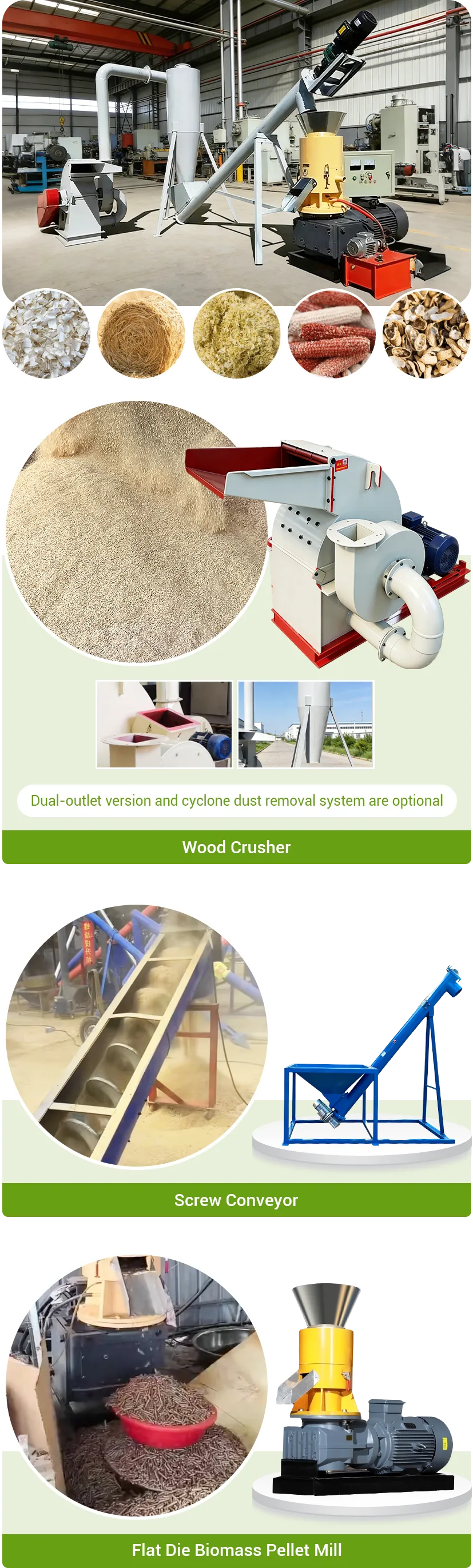

Small Biomass Pellet Production Line

It processes solid biomass materials such as sawdust, straw, bamboo powder, corn cobs, and peanut shells. The compact design requires little space and low investment, making it suitable for small processing sites, startup projects, and on farm pellet production.

Production Steps

- Check the raw materials and remove impurities to meet processing requirements.

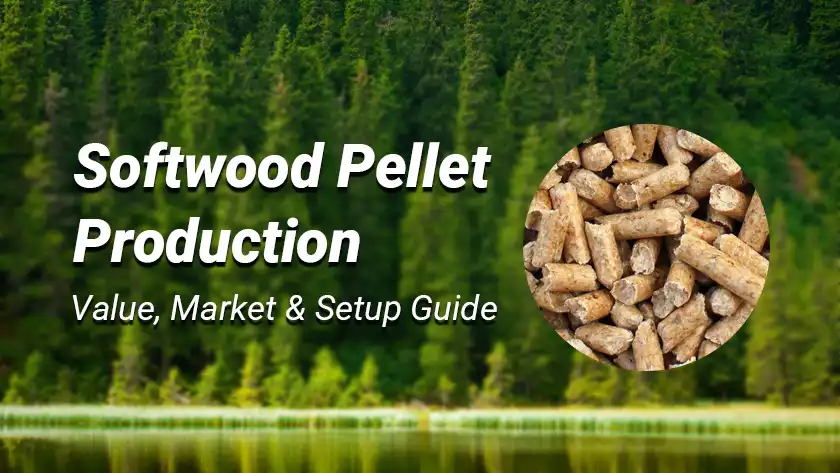

- Feed the materials into the hammer mill and grind them to the proper size for pelletizing.

- Use the screw conveyor to transfer the ground material to the pellet mill hopper, reducing manual handling.

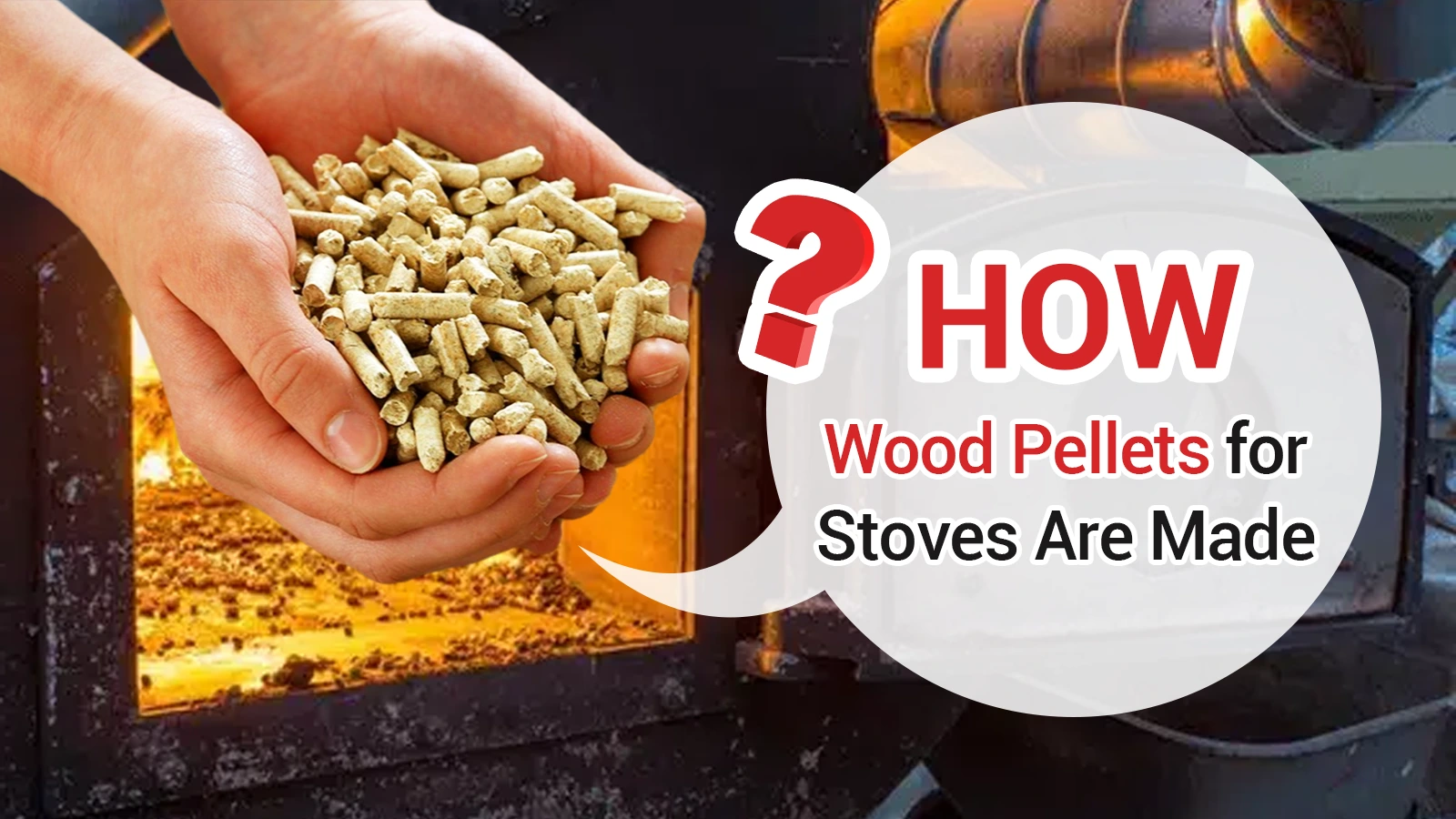

- Compress and form the material in the flat die biomass pellet machine to produce dense, durable pellets.

- Allow the finished pellets to cool naturally and store them properly to maintain quality.

Grinding size is controlled by the hammer mill screen, commonly 1.5 mm, 3 mm, or 5 mm. Pellet size can be adjusted by changing the die, with hole options from 2.5 to 10 mm.

This compact biomass pellet line is simple to operate, requires little space, and can be managed by one person. It handles materials such as sawdust, straw, bamboo powder, and corn cobs, helping lower fuel processing costs.

This wood crusher can be equipped with a dedicated wood feeding inlet, allowing whole logs to be fed directly and reducing the need for precutting.

We offer remote installation support, technical service, and spare parts to keep the line running reliably.

Video

Product Parameters

| Product | Capacity (kg/h) | Host Power (kw) |

| Wood Crusher | 300-400 | 7.5 |

| Screw Conveyor | 300-500 | 2.2 |

| Pellet Machine | 150-200 | 11 |

FAQ?

Is the production line expensive?

No. It is a small, compact system with a simple setup, so the investment is relatively low. Price depends on capacity, motor power, and optional parts, making it suitable for users with limited budgets or small scale production.

How is the energy consumption?

Energy use is low. All machines run on small motors, giving good efficiency for a small pellet line. Actual consumption varies with material hardness, moisture, and operating methods.

What materials can it process?

It can process sawdust, straw, bamboo powder, bark, corn cobs, peanut shells, and similar biomass. Screen size and die compression ratio can be adjusted to ensure good forming.

Can the line be expanded later?

Yes. Its modular design supports adding screening, cooling, storage, or automatic packing equipment.

Can it operate without a crusher?

Yes, if the raw material is already within 3 to 5 mm. large or long fiber materials will affect feeding and pellet quality without proper crushing.

Any tips for high fiber or harder materials?

Use the right screen size, keep feeding steady, and select a suitable die compression ratio. Adjust moisture, particle size, and feeding rate to avoid blockage or roller overload.

Is this small line suitable for commercial use?

Yes. It works well for local or small-scale businesses such as wood waste recycling, rural straw pellet production, or community heating fuel supply. With low investment and quick return, it is ideal for small workshops and startup projects.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.